Supply for Lyophilized royal jelly powder Rome

Supply for Lyophilized royal jelly powder Rome Detail:

[Products Name] Royal jelly powder,Lyophilized royal jelly powder

[Specification] 10-HDA 4.0%, 5.0%, 6.0%, HPLC

[Gerneral feature]

1. Low antibiotics, Chloramphenicol< 0.1ppb

2.Organic certified by ECOCERT, according to EOS & NOP organic standard;

3.100% pure with no additives;

4. More easily absorbed into the body than fresh royal jelly

5. Can be easily produced into tablets.

[Our advantages]

- 600 bee farmers, 150 units of bee-feeding groups located in natural mountains;

- Organic certificated by ECOCERT;

- NON-antibiotics, widely exported to Europe;

- Health Certificate, Sanitary Certificate and Quality Certificate are available.

[Lyophilized technology]

Lyophilized technology, also known as Freeze-drying, it is a dehydration process typically used to maintain activity of all nutrition ingredients in royal jelly, also to make the royal jelly convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase. This technology can maintain all activity of nutrition ingredient.

Lyophilized royal jelly powder is processed directly from fresh royal jelly.

3kgs fresh royal jelly is used to make 1kg lyophilized royal jelly powder.

During all the production process, there is no additives.

[Packing]

5kg/bag, 25kgs/drum

1kg/bag, 20kgs/carton

Main indices of physical and chemic in Lyophilized royal jelly

| Ingredients Indices | Lyophilized royal jelly | Standards | Results |

| Ash | 3.2 | <5 | Complies |

| Water | 4.1% | <7% | Complies |

| Glucose | 43.9% | <50% | Complies |

| Protein | 38.29% | >33% | Complies |

| 10-HDA | 6.19% | >4.2% | Complies |

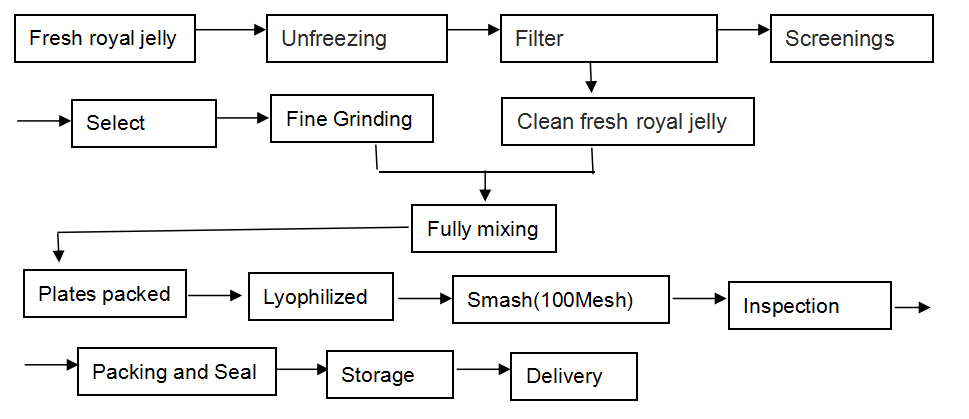

[Our work flow]

Our Lyophilized Royal Jelly Powder is produced in this way: we lyophilize the fresh royal jelly by advanced freeze-drying facilities without losing any nutritional ingredients, reserving the natural ingredients in utmost, and then make them into the form of powder, for any food additives are not needed to add.

The raw material we use is the natural fresh royal jelly which is up to the export standard . We process our products strictly according to export standard. Our workshop is up to the requirements of GMP.

Royal Jelly powder has been selected as drug excipients by many European and American pharmaceutical producing enterprises.Meanwhile it is applies to health food and cosmetics industries.

[Quality control]

Traceability record

GMP standard production

Advanced inspection equipment

[Function]

1.Enhances the immune system

2.Promotes wound healing

3.Has antitumor/anticancer properties

4.Lowers cholesterol levels

5.Increases fat metabolism

6.Is a powerful antioxidant

7.Regulates blood sugar levels

[Applications]

It’s widely used in health tonic, health pharmacy, hairdressing and cosmetic area, and mainly was applied in capsules, troche and oral liquids etc.

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Provider is supreme, Name is first", and will sincerely create and share success with all clientele for Supply for Lyophilized royal jelly powder Rome , The product will supply to all over the world, such as: Hungary, South Korea, Australia, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

Agriculture: Farming, Ranching playlist: https://www.youtube.com/playlist?list=PL897E774CDB19F283

Food & Beverage playlist: https://www.youtube.com/playlist?list=PL12ED9F0F94A97DA0

more at https://food.quickfound.net/

“Describes the interdependence of science and agriculture in modern life. Explains how the soy bean was cultivated in China and then introduced in the United States. Describes the plant’s characteristics and its value to soil conservation. Produced by Erpi Classroom Films, Inc. in collaboration with W.L. Burlison, Ph.D, University of Illinois.”

Reupload of a previously uploaded film with improved video & sound.

Public domain film from the Library of Congress Prelinger Archives, slightly cropped to remove uneven edges, with the aspect ratio corrected, and one-pass brightness-contrast-color correction & mild video noise reduction applied.

The soundtrack was also processed with volume normalization, noise reduction, clipping reduction, and/or equalization (the resulting sound, though not perfect, is far less noisy than the original).

https://creativecommons.org/licenses/by-sa/3.0/

https://en.wikipedia.org/wiki/Soybean

The soybean (U.S.) or soya bean (UK) (Glycine max) is a species of legume native to East Asia, widely grown for its edible bean which has numerous uses. The plant is classed as an oilseed rather than a pulse by the Food and Agricultural Organization (FAO).

Fat-free (defatted) soybean meal is a significant and cheap source of protein for animal feeds and many prepackaged meals; soy vegetable oil is another product of processing the soybean crop. For example, soybean products such as textured vegetable protein (TVP) are ingredients in many meat and dairy analogues. Soybeans produce significantly more protein per acre than most other uses of land.

Traditional nonfermented food uses of soybeans include soy milk, and from the latter tofu and tofu skin. Fermented foods include soy sauce, fermented bean paste, natto, and tempeh, among others. The oil is used in many industrial applications. The main producers of soy are the United States (35%), Brazil (27%), Argentina (19%), China (6%) and India (4%). The beans contain significant amounts of phytic acid, alpha-linolenic acid, and the isoflavones genistein and daidzein.

The plant is sometimes referred to as greater bean (大豆 – Chinese dàdòu and Japanese daizu). Both the immature soybean and its dish are called edamame in Japan, but in English, edamame refers only to a specific dish.

The English word “soy” is derived from the Japanese pronunciation of shōyu (醤油, しょうゆ?), the Japanese word for soya sauce; “soya” comes from the Dutch adaptation of the same word…

For human consumption, soybeans must be cooked with “wet” heat to destroy the trypsin inhibitors (serine protease inhibitors). Raw soybeans, including the immature green form, are toxic to humans, swine, chickens, and in fact, all monogastric animals.

Soybeans are considered by many agencies to be a source of complete protein. A complete protein is one that contains significant amounts of all the essential amino acids that must be provided to the human body because of the body’s inability to synthesize them. For this reason, soy is a good source of protein, amongst many others, for vegetarians and vegans or for people who want to reduce the amount of meat they eat…

Soy protein is essentially identical to that of other legume seeds. Moreover, soybeans can produce at least twice as much protein per acre than any other major vegetable or grain crop besides hemp, five to 10 times more protein per acre than land set aside for grazing animals to make milk, and up to 15 times more protein per acre than land set aside for meat production…

If you are looking for a Male Enhancement Pill item to help you increase your sexual interest and reinstate your sex lifestyle, and you are seriously considering selecting between the best Mood enhancement pill or Better Sex Pill (popularly known as androgenic hormone or testosterone patch); then you will need to create sure you know all you need to know about these Male Enhancement products before you create your option Pleae get in touch with over web page :https://www.impulsemarket.com/ You can get in touch with soon:1-855-55-HERBS

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.