8 Years Manufacturer Stevia Extract Manufacturer in Suriname

8 Years Manufacturer Stevia Extract Manufacturer in Suriname Detail:

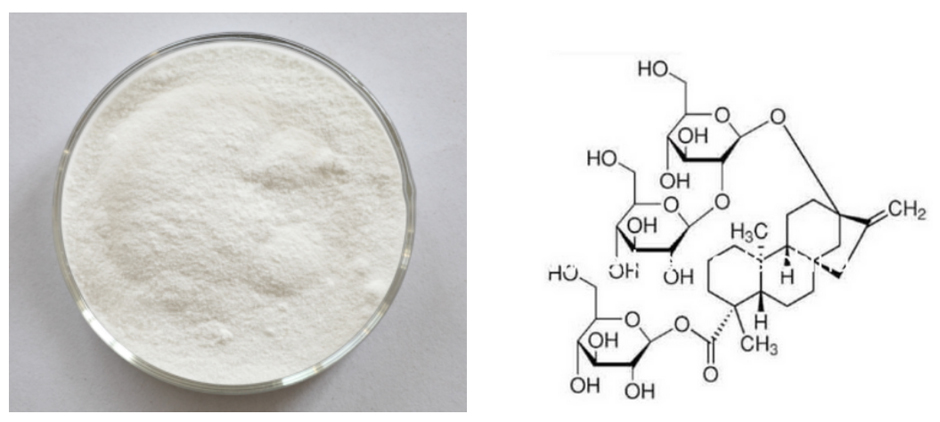

[Latin Name] Stevia rebaudiana

[Plant Source]from China

[Specifications] 1.Stevia Extract Powder (Steviosides)

Total Steviol Glycosides 80%, 90%, 95%

2. Rebaudioside-A

Rebaudioside-A 40%, 60%, 80%, 90%, 95%, 98%

3. Stevioside 90%

One monomer in Steviol Glycosides

[Appearance] Fine white powder

Plant Part Used:Leaf

[Particle size] 80 Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Shelf life] 24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[Net weight] 25kgs/drum

Stevia Extract

[Characteristics]

Stevia sugar features high sweetness and low calorie and its sweetness is 200 350 times of that of cane sugar but its calorie is only 1/300 of that of cane sugar.

The component of stevia extract that gives it its sweetness is a mixture of various steviol glycosides. The components of sweetness in stevia leaves are stevioside, rebaudioside A, C, D, E and dulcoside A. Rebaudioside C, D, E and dulcoside A are small in quantity. The principal components are stevioside and rebaudioside A.

The quality of stevioside and rebaudiosideA is better than those of other components, which are commercially extracted and used in various applications.

The steviol glycosides present in stevia extract are referred to as “steviosides” or ¡°stevia extract¡±. Among these “steviosides”, the most common is Stevioside followed by RebaudiosideA. The Stevioside has a slight and pleasant herbal taste and the Rebaudioside-A has no herbal taste.

Although Rebaudioside C and dulcoside A are small in quantity in stevia extract, they are the major components giving bitter aftertaste.

[Function]

A large number of pharmaceutical tests have proved that stevia sugar has no side effects, carcinogens, and is safe for eating.

Compared with cane sugar, it can save 70% of the cost. With pure white color, pleasing taste and no peculiar smell, Stevia sugar is a new sugar source with broad perspective for development. Stevia rebaudianum sugar is the natural low hotsweet agent mostly similar to the flavor of cane sugar, approved to be used by State Ministry of Health and Ministry of Light Industry.

It is the third natural succedaneum of cane sugar and beet sugar with development and health care value, extracted from the leaves of the herbal vegetable of the composite family-stevia rebaudianum.

Product detail pictures:

Related Product Guide:

To create much more price for clients is our company philosophy; purchaser growing is our working chase for 8 Years Manufacturer Stevia Extract Manufacturer in Suriname , The product will supply to all over the world, such as: Thailand, Pretoria, Swaziland, With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to supply you both better solutions and service, because we've been more and more powerful, specialist and experience in domestic and international.

DIY 0utdoor Slime, No Borax, Fluffy Slime Recipes, How to Make Slime WITHOUT B – How to make slime

DIY 0utdoor Slime, No Borax, Fluffy Slime Recipes, How to Make Slime WITHOUT B – How to make slime

DIY 0utdoor Slime, No Borax, Fluffy Slime Recipes, How to Make Slime WITHOUT B – How to make slime

Hi everyone! In today’s video, DIY 0utdoor Slime, No Borax, Fluffy Slime Recipes, How to Make Slime WITHOUT Borax!

About Slime:

Slime was a toy product manufactured by pillo, sold in a plastic trash can and introduced in the winter of 1976. It consisted of a non-toxic viscous, squishy and oozy green or other color material made primarily from guar gum.[1] Different variations of Slime were released over the years, including Slime containing rubber insects, eyeballs, and worms and Masters of the Universe Slime for Hordak’s Slime Pit playset in the 1980s.

The late 1970s also introduced a Slime Monster board game; the object of the game was to avoid having your game piece slimed on by a foot-tall plastic monster that had slime oozing from its mouth. Other toy companies have produced their own slime such as the Ecto-Plazm play gel[2] sold with select figures in Kenner’s Real Ghostbusters toyline. Playmates’ Teenage Mutant Ninja Turtles figure line also had Retro-Mutagen slime sold in containers and included with playsets.

he main components are the polysaccharide guar gum and sodium tetraborate. As an alternative to the polysaccharide, other alcohol-group containing polymers (such as polyvinyl alcohol) may be used to a similar result. These non-polysacharide polymer products are more often referred to as flubber.

Polyvinyl acetate (Elmer’s glue), borax and water can also be used to approximate Slime’s characteristics.

Please join to my channel from link below;

HoppiTV :

FunnyKids TV :

Besides DIY 0utdoor Slime, No Borax, Fluffy Slime Recipes, How to Make Slime WITHOUT Borax!you can also have a look;

Real!! 5 Ways No Glue Slime, 5 No Glue Slime Recipes, No Glue, No Borax, No Cornstarch top 5

DIY NO GLUE GOLDEN SLIME, MUST WATCH , WITHOUT GLUE , WITHOUT BORAX, amazing no glue slime

Colgate Toothpaste and Salt Slime, How to Make a Slime with Toothpaste and Salt,2 ingredients Slime

Shampoo Fluffy Slime with Clear Glue, No Borax, No Salt, DIY Shampoo Slime, No Shaving Cream

No Borax Slime,No Borax Slime Recipe,No Borax Slime Recipes,Popular No Borax Slime,Popular No Borax Slime Recipes,Popular No Borax Slime Recipe,Testing Popular No Borax Slime Recipes,testing slime recipes,How To Make Slime Without Borax,Slime Without Borax,Make Slime Without Borax,NO GLUE SLIME,NO GLUE SLIME RECIPE,NO GLUE SLIME RECIPES,POPULAR NO GLUE SLIME,TESTING POPULAR NO GLUE SLIME,how to make slime without glue,no borax no glue slime,slime masters

DIY 0utdoor Slime, No Borax, Fluffy Slime Recipes, How to Make Slime WITHOUT Borax!

Subscribe & More Videos: https://goo.gl/i5Un8y

Thank for watching, Please Like Share And SUBSCRIBE!!!

#noboraxslimerecipes, #noglueslime

Chemistry playlist: https://www.youtube.com/playlist?list=PL_hX5wLdhf_KyuOalV6rwHjo810Zaa6xq

more at https://scitech.quickfound.net/

Overview of how plastics & synthetic rubbers are made.

Reupload of a previously uploaded film with improved video & sound.

Public domain film from the Library of Congress Prelinger Archives, slightly cropped to remove uneven edges, with the aspect ratio corrected, and one-pass brightness-contrast-color correction & mild video noise reduction applied.

The soundtrack was also processed with volume normalization, noise reduction, clipping reduction, and/or equalization (the resulting sound, though not perfect, is far less noisy than the original).

https://creativecommons.org/licenses/by-sa/3.0/

https://en.wikipedia.org/wiki/Polymer

A polymer is a large molecule (macromolecule) composed of repeating structural units. These sub-units are typically connected by covalent chemical bonds. Although the term polymer is sometimes taken to refer to plastics, it actually encompasses a large class of compounds comprising both natural and synthetic materials with a wide variety of properties.

Because of the extraordinary range of properties of polymeric materials, they play an essential and ubiquitous role in everyday life. This role ranges from familiar synthetic plastics and elastomers to natural biopolymers such as nucleic acids and proteins that are essential for life.

Natural polymeric materials such as shellac, amber, wool, silk and natural rubber have been used for centuries. A variety of other natural polymers exist, such as cellulose, which is the main constituent of wood and paper. The list of synthetic polymers includes synthetic rubber, Bakelite, neoprene, nylon, PVC, polystyrene, polyethylene, polypropylene, polyacrylonitrile, PVB, silicone, and many more.

Most commonly, the continuously linked backbone of a polymer used for the preparation of plastics consists mainly of carbon atoms. A simple example is polyethylene (‘polythene’ in British English), whose repeating unit is based on ethylene monomer. However, other structures do exist; for example, elements such as silicon form familiar materials such as silicones, examples being Silly Putty and waterproof plumbing sealant. Oxygen is also commonly present in polymer backbones, such as those of polyethylene glycol, polysaccharides (in glycosidic bonds), and DNA (in phosphodiester bonds).

Polymers are studied in the fields of polymer chemistry, polymer physics, and polymer science…

Polymerization is the process of combining many small molecules known as monomers into a covalently bonded chain or network. During the polymerization process, some chemical groups may be lost from each monomer. This is the case, for example, in the polymerization of PET polyester. The monomers are terephthalic acid (HOOC-C6H4-COOH) and ethylene glycol (HO-CH2-CH2-OH) but the repeating unit is -OC-C6H4-COO-CH2-CH2-O-, which corresponds to the combination of the two monomers with the loss of two water molecules. The distinct piece of each monomer that is incorporated into the polymer is known as a repeat unit or monomer residue…

https://en.wikipedia.org/wiki/Synthetic_rubber

Synthetic rubber is any type of artificial elastomer, invariably a polymer. An elastomer is a material with the mechanical (or material) property that it can undergo much more elastic deformation under stress than most materials and still return to its previous size without permanent deformation.About 15 billion kilograms of rubbers are produced annually, and of that amount two thirds is synthetic…

Natural vs synthetic rubber

Natural rubber, coming from latex, is mainly poly-cis-isoprene containing traces of impurities. Although it exhibits many excellent properties, natural rubber is often inferior to synthetic rubbers, especially with respect to its thermal stability and its compatibility with petroleum products.

Synthetic rubber is made by the polymerization of a variety of petroleum-based precursors called monomers. The most prevalent synthetic rubbers are styrene-butadiene rubbers (SBR) derived from the copolymerization of styrene and 1,3-butadiene. Other synthetic rubbers are prepared from isoprene (2-methyl-1,3-butadiene), chloroprene (2-chloro-1,3-butadiene), and isobutylene (methylpropene) with a small percentage of isoprene for cross-linking. These and other monomers can be mixed in various proportions to be copolymerized to produce products with a range of physical, mechanical, and chemical properties. The monomers can be produced pure and the addition of impurities or additives can be controlled by design to give optimal properties. Polymerization of pure monomers can be better controlled to give a desired proportion of cis and trans double bonds…

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.