Good Quality Organic Ginseng extract Wholesale to Cape Town

Good Quality Organic Ginseng extract Wholesale to Cape Town Detail:

[Latin Name] Panax ginseng CA Mey.

[Plant Source] Dried Root

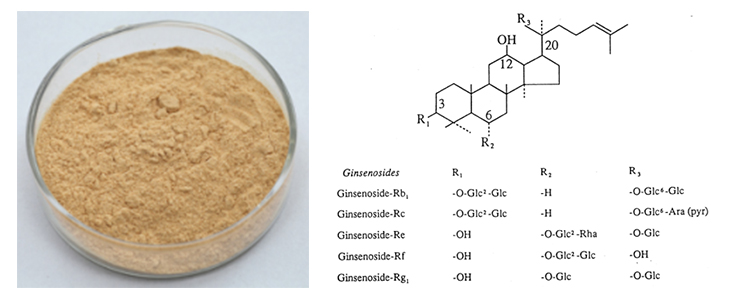

[Specifications] Ginsenosides 10%–80%(UV)

[Appearance] Fine Light Milk Yellow Powder

[Particle size] 80 Mesh

[Loss on drying] ≤ 5.0%

[Heavy Metal] ≤20PPM

[Extract solvents] Ethanol

[Microbe] Total Aerobic Plate Count: ≤1000CFU/G

Yeast & Mold: ≤100 CFU/G

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Shelf life]24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[What is Ginseng]

In terms of modern scientific research, ginseng is known to be an adaptogen. Adaptogens are substances that assist the body to restore itself to health and work without side effects even if the recommended dose is widely exceeded.

Ginseng due to its adaptogens effects is widely used to lower cholesterol, increase energy and endurance, reduce fatique and effects of stress and prevent infections.

Ginseng is one of the most effective antiaging supplements. It can alleviate some major effects of aging, such as degeneration of the blood system, and increase mental and physical capacity.

Other important benefits of ginseng is its support in cancer treatment and its effects on sports performance.

[Application]

1. Applied in food additives, it owns the effect of antifatigue, anti-aging and nourishing brain;

2. Applied in pharmaceutical field, it is used to treat coronary heart disease, angina cordis, bradycardia and high heart rate arrhythmia, etc.;

3. Applied in cosmetics field, it owns the effect of whitening, dispelling spot, anti-wrinkle, activating skin cells, making skin more tender and firm.

Product detail pictures:

Related Product Guide:

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for Good Quality Organic Ginseng extract Wholesale to Cape Town , The product will supply to all over the world, such as: United States, Costa rica, Jamaica, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

क्या आपको पता है कि कद्दू के बीज से बढ़ाएं अपने सेक्स पावर को ?How do you know that pumpkin seeds to increase the power of your sex? surprised to learn of the miraculous benefits of pumpkin seeds

सेक्स पावर बढ़ाने से लेकरमधुमेह और कोलेस्ट्रॉल तक कद्दू के बीज के चौकाने वाले फायदे, Health Benefits of Pumpkin Seeds

Pumpkin Seeds Health Benefits

• Good Blood Builder.

• Promote Good Sleep.

• Stimulates Hair Growth.

• They up your energy.

• Improves Bladder and Prostate Health.

• Bone Health.

• Help Maintain a Strong Heart.

.pumpkin seed health benefit of sperm

#baby india youtube channel

Did you ever wonder what would happen in your everyday life if you add more science?

Stop having a boring life! Add awesome science to your everyday conversations and subscribe to Bill & Bob on YouTube.

Every Situation is better with science.

Off: “So, you guys are on a break. And Bill? What are you doing?”

Bill: “I’m making tea.”

Off: “Aaaaand?”

Bill: “I don’t know. What else I am supposed to be doing?”

Off: “This is Booooooring! Tell me more science”

Bill: “Well, actually I’m dissolving 1,3,7- Trimethylpurine-2, 6-dione, Polyhydroxyphenols, amino acids, polysaccharides and Hydrogen oxide at 100 Degrees Centigrade. And mixing in some 2, 3, 4, 5, 6-Pentahydroxyhexanal … for taste”

Bob: “Hhm, sounds chemical.”

Bill: “Well, actually everything around us is build up from chemical substances, Bob. Even natural thinks, like an apple are complex combinations of hundreds of different chemicals. Our bodies are chemical too, Bob.

Off: “Bill, do you know what you are?”

Bill: “What am I?”

Off: “Do you know what you are, Bill?”

Bill: “What did I do wrong?”

Off: “You are a scientist!”

Bill: “Yeahhhh! I’m a scientist!”

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.