Best Price for Blackcurrant Extract Supply to Cancun

Best Price for Blackcurrant Extract Supply to Cancun Detail:

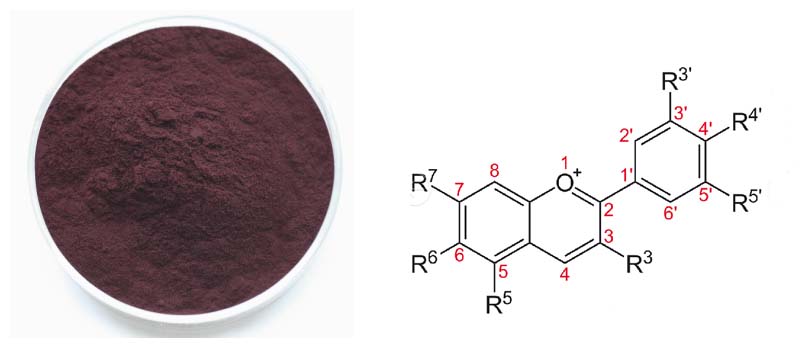

[Latin Name] Ribes nigrum

[Specification] Anthocyanosides≥25.0%

[Appearance] Purple black fine powder

Plant Part Used: Fruit

[Particle size] 80Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Shelf life] 24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[Net weight] 25kgs/drum

[What is Black currant?]

The black currant bush is a 6-foot tall perennial that entered the world somewhere in the regions that include northern Asia and central and northern Europe. Its flowers display five reddish-green to brownish petals. The celebrated black currant fruit is a glossy-skinned berry that carries several seeds laden with marvelous nutritional and curative treasures. An established bush can produce ten pounds of fruit per season

[Benefits]

1. Vision help my eyesight

2. Urinary Tract Health

3. Ageing & Brain Function.

4. Natural Brain Boost

5. Digestion & Fighting Cancer

6. Reducing Erectile Dysfunction

Product detail pictures:

Related Product Guide:

It really is a good way to further improve our goods and service. Our mission would be to acquire inventive items to buyers with a very good encounter for Best Price for Blackcurrant Extract Supply to Cancun , The product will supply to all over the world, such as: Peru, Slovenia, Bangladesh, Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

https://www.ebay.com/sch/male-enhancement-specialists Kings Power Plus Sex Supplement 30 tbs

KINGS POWER PLUS

MALE ENHANCEMENT FORMULA

30 TABLETS

For Increased Sexual Function and Performance Dietary Supplement.

Ignite Sexual Performance

Increase Erection Size, Firmness and Girth

Produce Longer Lasting and More Intense Erections

Give Sustained Erections in 15 Minutes or Less

Create an Intense Sensation That Most Sexual Partners Will Never Feel

Natural And Safe

Alcohol Friendly

About The Male Enhancement Specialists: Male Enhancement Specialists: We help men all over the world achieve optimum sexual performance. Only the best for our clients because “You deserve to have a great sex life”!

Warning: Long, science-heavy video. No funny cats or guys getting hit in the nuts.

Artificial sweeteners, or as they are usually referred to in the literature “non-caloric” sweeteners or “high-intensity” sweeteners, address the problem of sugar calorie excess in our diet. They’ve been demonstrated to support weight loss or maintenance, reduce cavities and can be part of a healthy lifestyle.

Much focus has been on

CSPI report: https://www.cspinet.org/reports/chemcuisine.htm

I disagree with CSPI on about 25% of their rankings, but I appreciate that they take a very conservative stance.

Citations:

Aspartame:

1. Comp Funct Genomics. 2010. In vivo cytogenetic studies on aspartame.

2. Drug Chem Toxicol. 2004 Aug;27(3):257-68. Genotoxicity of aspartame.

3. Am J Ind Med. 2010 Dec;53(12):1197-206. Aspartame administered in feed, beginning prenatally through life span, induces cancers of the liver and lung in male Swiss mice.

4. Toxicol In Vitro. 2011 Feb;25(1):286-93. In vitro effect of aspartame in angiogenesis induction.

Sucralose:

5. Regul Toxicol Pharmacol. 2009 Oct;55(1):1-5. An overview of the safety of sucralose.

6. Regul Toxicol Pharmacol. 2009 Oct;55(1):6-12. Expert panel report on a study of Splenda in male rats.

7. Food Chem Toxicol. 2000;38 Suppl 2:S53-69. Acute and subchronic toxicity of sucralose.

8. Food Chem Toxicol. 2000;38 Suppl 2:S71-89. A combined chronic toxicity/carcinogenicity study of sucralose in Sprague-Dawley rats.

9. Food Chem Toxicol. 2000;38 Suppl 2:S91-7. A carcinogenicity study of sucralose in the CD-1 mouse.

AceK:

10. Horm Metab Res. 1987 Jun;19(6):233-8. The effect of artificial sweetener on insulin secretion. 1. The effect of acesulfame K on insulin secretion in the rat (studies in vivo).

11. Food Chem Toxicol. 1997 Dec;35(12):1177-9. In vivo cytogenetic studies on mice exposed to acesulfame-K–a non-nutritive sweetener.

General reviews:

12. Ann Oncol. 2004 Oct;15(10):1460-5. Artificial sweeteners–do they bear a carcinogenic risk?

13. Yale J Biol Med. 2010 Jun;83(2):101-8. Gain weight by “going diet?” Artificial sweeteners and the neurobiology of sugar cravings

14. Int J Obes Relat Metab Disord. 1996 Mar;20 Suppl 2:S12-7. Effect of sucrose and sweeteners on appetite and energy intake.

15. Am J Clin Nutr. 2009 Jan;89(1):1-14. Nonnutritive sweetener consumption in humans: effects on appetite and food intake and their putative mechanisms.

16. Physiol Behav. 2010 Apr 26;100(1):55-62. High-intensity sweeteners and energy balance.

17. Physiol Behav. 2009 Dec 7;98(5):618-24. Effect of moderate intake of sweeteners on metabolic health in the rat.

18. Food Addit Contam. 2006 Apr;23(4):327-38. The intake of intense sweeteners – an update review.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!