Professional Design Lyophilized royal jelly powder Supply to Jersey

Professional Design Lyophilized royal jelly powder Supply to Jersey Detail:

[Products Name] Royal jelly powder,Lyophilized royal jelly powder

[Specification] 10-HDA 4.0%, 5.0%, 6.0%, HPLC

[Gerneral feature]

1. Low antibiotics, Chloramphenicol< 0.1ppb

2.Organic certified by ECOCERT, according to EOS & NOP organic standard;

3.100% pure with no additives;

4. More easily absorbed into the body than fresh royal jelly

5. Can be easily produced into tablets.

[Our advantages]

- 600 bee farmers, 150 units of bee-feeding groups located in natural mountains;

- Organic certificated by ECOCERT;

- NON-antibiotics, widely exported to Europe;

- Health Certificate, Sanitary Certificate and Quality Certificate are available.

[Lyophilized technology]

Lyophilized technology, also known as Freeze-drying, it is a dehydration process typically used to maintain activity of all nutrition ingredients in royal jelly, also to make the royal jelly convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase. This technology can maintain all activity of nutrition ingredient.

Lyophilized royal jelly powder is processed directly from fresh royal jelly.

3kgs fresh royal jelly is used to make 1kg lyophilized royal jelly powder.

During all the production process, there is no additives.

[Packing]

5kg/bag, 25kgs/drum

1kg/bag, 20kgs/carton

Main indices of physical and chemic in Lyophilized royal jelly

| Ingredients Indices | Lyophilized royal jelly | Standards | Results |

| Ash | 3.2 | <5 | Complies |

| Water | 4.1% | <7% | Complies |

| Glucose | 43.9% | <50% | Complies |

| Protein | 38.29% | >33% | Complies |

| 10-HDA | 6.19% | >4.2% | Complies |

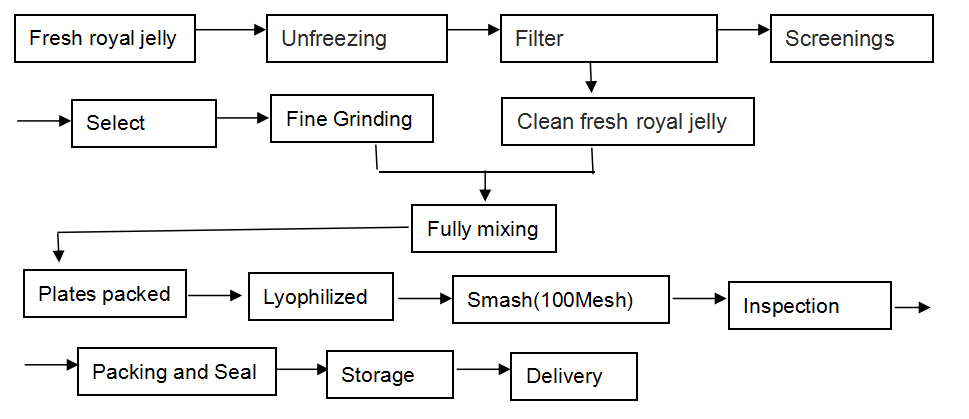

[Our work flow]

Our Lyophilized Royal Jelly Powder is produced in this way: we lyophilize the fresh royal jelly by advanced freeze-drying facilities without losing any nutritional ingredients, reserving the natural ingredients in utmost, and then make them into the form of powder, for any food additives are not needed to add.

The raw material we use is the natural fresh royal jelly which is up to the export standard . We process our products strictly according to export standard. Our workshop is up to the requirements of GMP.

Royal Jelly powder has been selected as drug excipients by many European and American pharmaceutical producing enterprises.Meanwhile it is applies to health food and cosmetics industries.

[Quality control]

Traceability record

GMP standard production

Advanced inspection equipment

[Function]

1.Enhances the immune system

2.Promotes wound healing

3.Has antitumor/anticancer properties

4.Lowers cholesterol levels

5.Increases fat metabolism

6.Is a powerful antioxidant

7.Regulates blood sugar levels

[Applications]

It’s widely used in health tonic, health pharmacy, hairdressing and cosmetic area, and mainly was applied in capsules, troche and oral liquids etc.

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Professional Design Lyophilized royal jelly powder Supply to Jersey , The product will supply to all over the world, such as: Croatia, Liberia, Bolivia, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

Research showing the effectiveness of Pycnogenol and Vitamin C for allergies and hey fever. Enhanced by the Isotonix delivery system.

https://www.iitutor.com

Condensation polymers are formed when monomers join together, and in the process also form a separate small molecule such as a water molecule. The ends of the monomer molecules must have functional groups that can join with other functional groups on neighbouring molecules.

Condensation polymerisation is the process in which two monomers combine with the elimination of a smaller molecule. One way that two different monomers can combine and in doing so lose a molecule of water and represents condensation polymerisation. This process continues and each remaining end joins with another monomer—each time lengthening the chain. One way to think of this is a “head-to-tail” joining.

Synthetic condensation polymers include nylons and polyesters. Natural condensation polymers include cellulose, cotton, wool, and silk.

Cellulose is a complex carbohydrate or polysaccharide. It is the most abundant biopolymer in nature. Carbohydrates consist of molecules containing C, H and O atoms. Carbohydrates contain many alcohol functional groups.

• Cellulose consists of long chains of β-glucose monomers.

• Glucose is an example of a simple carbohydrate or monosaccharide.

Structure of glucose :

Glucose (C6H12O6) is a ring molecule. The carbon atoms in the ring are numbered as shown. The –OH functional groups may be orientated above or below the plane of the ring. These different orientations at C, produce the alpha and beta forms of the glucose monomers.

• Glucose is an organic compound

• Ring can open up in solution to form a straight-chain structure. Open and chain forms are in equilibrium that cause glucose to exist as anomers, β-glucose and α-glucose.

Biopolymer is a naturally occurring polymer such as cellulose, starch, gluten, DNA and protein.

Formation of cellulose:

Cellulose is a condensation polymer which is formed when glucose monomers condense together through beta-1,4-glycosidic bonds. This involves a reaction between the –OH groups at the C1 and C4 carbons of adjacent glucose molecules.

The process begins by the condensation reaction between two glucose monomers to form a beta-maltose dimer. A water molecule is eliminated during this reaction. More glucose monomers condense and the chain grows until about 10 000 glucose monomers are linked in long, unbranched, ribbon-like strands.

Strong hydrogen bonding exists between –OH groups of neighbouring, close-packed strands. This produces a water-insoluble polymer with great strength and rigidity. Plants use cellulose as a structural carbohydrate for their cell walls.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!