2016 Latest Design Organic Ginkgo Biloba Extract Wholesale to Las Vegas

2016 Latest Design Organic Ginkgo Biloba Extract Wholesale to Las Vegas Detail:

[Latin Name] Cinnamomun camphcra

[Plant Source] It is extracted from Ginkgo Biloba Leaf.

[Specifications]

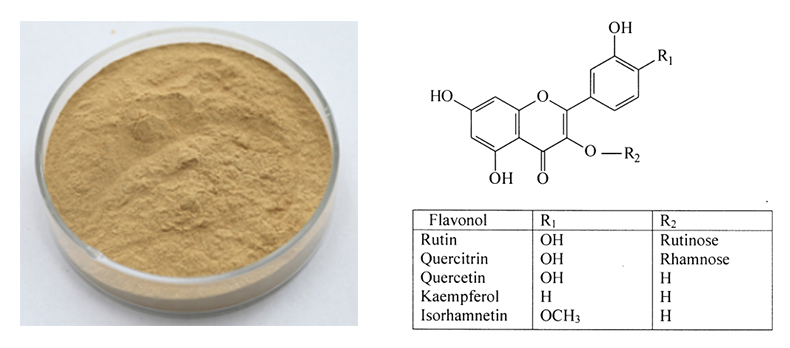

1, Ginkgo Biloba Extract 24/6

Total Ginkgo flavone glycosides 24%

Total terpene lactones 6%

2, Ginkgo Biloba Extract 24/6

Total Ginkgo flavone glycosides 24%

Total terpene lactones 6%

Ginkgolic acid 5ppm

3,CP2005

Total Ginkgo flavone glycosides 24%

Quercatin: kaemperol 0.8–1.5

Total terpene lactones 6%

Ginkgolic acid <5ppm

4.Germany Standard

Total Ginkgo Flavone Glycosides 22.0%-27%

Total Terpene Lactones 5.0%-7.0%

Bilobalides 2.6%-3.2%

Ginkgolic acid <1ppm

5.Water-Soluble Ginkgo Biloba Extract 24/6

Water Solubility: 5g Ginkgo Biloba Extract will be dissolved completely in 100g water

Total Ginkgo Flavone Glycosides 24.0%

Total Terpene Lactones 6.0%

Ginkgolic acid <5.0ppm

[Appearance] Light yellow fine powder

[Particle size] 80 Mesh

[Loss on drying] £ 5.0%

[Heavy Metal] £10PPM

[Extract solvents] Ethanol

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Package] Packed in paper-drums and two plastic-bags inside.

[Function]

Expanding blood vessel, resisting insufficient blood and oxygen deficit, increasing blood flow, improving cerebral arteries and distal

blood flow. Promoting cerebral circulation metabolism, improving memory function, resisting depression, resisting lipidic overoxidation,

protecting liver damage.

In clinic, curing high blood pressure, hyperlipoidemia, coronary heart disease, angina pectoris, arterial sclerosis, cerebral embolism,

senile dementia, primary and periodic dropsy, acute drumming in the ears, epicophosis, a variety of body function in disorder, dizziness

and so on.

Product detail pictures:

Related Product Guide:

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for 2016 Latest Design Organic Ginkgo Biloba Extract Wholesale to Las Vegas , The product will supply to all over the world, such as: Bangladesh, Bolivia, Kuala Lumpur, Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

Stevia grows best in upland areas in sub-tropical climate. In other places it can be grown as an annual. The plant prefers a lightly textured, well-drained soil to which organic matter has been added. It needs ample water so that the soil is consistently moist, but not wet. In hot, sunny climates it will do best in semi-shade. Propagation is from seed sown in spring, but germination rates can be low-expect half the seeds sown not to germinate. Plant seedlings out once all danger of frost is over. Leaves are best harvested just before flowering. The plants will also grow from cuttings,which are best taken in late winter.The concentration of stevioside in the leaves of Stevia increasing when the plants are grown under long day condition.While, cultivating stevia on a large scale, it can be grown in well-drained red soil and sandy loam soil. The soil should be in the pH range of 6.5-7.5. Saline soils should be avoided to cultivate this plant.

Stevia can be successfully cultivated all around the year all over India expect theareas, which receive snowfall, or temperatures go below 5 degree Celsius in winter.The summer temperatures actually do not affect this plant if the high summer temperatures have already been factored in the cultivation practices.Since seed germination rate is very poor,it is propagated vegetative. Though stem cuttings are used for vegetative tissue culture plants have proven to be the best planting material for Stevia. Tissue culture plants of Stevia are genetically pure, free from pathogens and haveexcellent vigor. The tissue culture plants can be planted throughout the year,expect during peak summer. An ideal planting density is 40,000 plants per acre with spacing of 25×40 cm in a raised bed system. The soil can be enriched with abasal dressing of 25 tons of well rotten farmyard manure/hectare

Soil Type

Stevia requires very good drainage any soil that retain the moisture for very long period of time are unsuitable for Stevia cultivation and should be religiously avoided.Red soil and sandy loam with a 6-7 pH are best for the cultivation of Stevia.

Raised bed preparation

Forming raised beds is the most economical way to grow Stevia. The raised bed should be of 15 cm in height and 60 cm in width. The distance between each plant 23 cm. This would give a plant population of around 40,000 per acre.

Planting Material

There are basically two options for multiplication. The first is the tissue culture and second the stem cutting. Tissue culture is the best option but many farmers are tempted to try the stem cutting method for multiplication. As per practical experience, stem cutting is sometimes more expensive to produce than the tissue culture since the success rate of the stem cuttings establishment is very low, it takes minimum of 25 weeks for the stem cutting to develop in proper feeding roots for transplantation (younger stem cuttings transplants have shown more than 50% mortality in first few weeks of transplants in main field).

Harvesting

Another important aspect of harvesting is the timing of harvest. It should be noted that at no point of time plants should be allowed to flower since after flowering the Stevioside percentage goes down rapidly and leaves are rendered unmarketable. Leaves are harvested by plucking in a small quantity, or the entire plant with the side branches is cut leaving 10 to 15 cm from the base.The first harvesting can be done four to five months after planting. Subsequent harvesting can be done every three months, for five consecutive years. The sweetener in the leaf is maximum till the plant flowers. Just before flowering, the plant should be cut completely leaving 10 cm from the ground. The new flush of leaves will sprout from here. The new plant will be ready for harvest again in three months. The plant yields around 3000 kg of dried leaves from an acre of plantation every year. Harvesting should be done as late as possible, since cool autumn temperatures and shorter days tend to intensify the sweetness of the plants as they evolve into a reproductive state.

Unlocking the sweetness in your harvest

Once all leaves have been harvested it’s required to dry them. This can be

accomplished on a net. The drying process is not one that requires excessive heat;more important is good air circulation. On a moderately warm fall day, stevia crop can be quick dried in the full sun in about 12 hours. (Drying times longer than that will lower the stevioside content of the final product.)

Crushing the dried leaves is the final step in releasing stevia’s sweetening power. The

dried leaves are powdered, sieved and the fine powder is stored in containers. This can be done either by hand or, for greater effect, in a coffee grinder or in a special blender for herbs.

Web: https://www.natureherbs.org | www.natureherbs.co

Email : natureherbs@ymail.com

Watsapp: +91 841 888 5555

Skype: nature.herbs

IRI GROUP is a leading manufacturer, supplier & service provider of water treatment plant, food & beverges processing plants and machines in India. Our range includes Industrial R.O. plants, DM Plants, Water treatment plants, Packaged drinking water plant ( Mineral Water Plant), Rainwater Harvesting System, Softener, ETP, STP, Bottling Machine, Soda Making Plant, RTS Juice Line, Food Processing Machinery, fruit & vegetable washer, Pulpers, Steam jacketed kettle, Pasteurizer, Boiler, Retort, Fruit mill, Blancher, Pea podder, fruit corer & sizer, Slicer, Juice extractor etc. Apart from supplying a complete range of food processing equipment with highly expertise professionals to give best solution from the existing systems in the organization.

We are also engaged in undertaking turnkey projects for Food Processing Machinery. These include turnkey projects for Mango processing plant, Fruit processing plant, Tomato processing plant, Pineapple processing plant, Guava processing Equipment, lime Processing Equipment, Amla Processing Equipment, Canning line for pulp and juice. Carbonated soft drink plant and others. We are rated among the topmost Water Treatment and food processing Plant manufacturers and suppliers based in India.

PACKAGING SEGMENT

• Bottle Rinsing Filling & Capping Machine ( 18, 30, 40, 50, 60 BPM )

• Water / Soda / Carbonated Beverage Packaging Machines

• Pet Blowing Machine

• Pouch Packing Machine

• Cup/Glass Filling Machine

• Jar Filling Machine

• Juice Filling Machine

• Chilling Plant ( Chiller )

• Cooling Towers

Contact Us :

Er. Manish Pandey

IRI GROUP OF BUSINESS CONSULTANT

( An ISO 9001 : 2008 Certified Company )

Address : A – 1788 Awas Vikas, Naubasta, Kanpur U.P. India

Ph : 09198529180, 09305155545, 0512-6452321

Mail : ermanishpandey18@gmail.com,

Web : https://www.irigroup.co.in

We have vast coverage of services in major cities of India like Agra, Aligarh, Allahabad, Bareilly, Budaun, Bijnor, Bulandshahar, Etawah, Faizabad, Farrukhabad, Firozabad, Ghaziabad, Gorakhpur, Jhansi, Kanpur, Lucknow, Lalitpur, Mathura, Merrut, Moradabad, Muzaffarnagar, Noida, Pilibhit, Rampur, Saharanpur, Shahjahanpur, Varanasi, Delhi, Andhra Pradesh, Assam, Bihar, Chhattisgarh, Gujrat, Jaipur Haryana, Himachal Pradesh, Madhya Pradesh, Manipur, Orissa, Punjab, Rajasthan, Uttar Pradesh, Uttarakhand, Uttaranchal, Chandigarh, Amritsar, Bhopal, Calcutta, Faridabad, Gurgaon, Gwalior, Hamirpur, Hyderabad, Indore, Ludhiana, Raebareli, Rajkot, Ranchi, Ujjain, Surat, Nepal etc.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

![[Latin Name] Cinnamomun camphcra3](http://cdn.goodao.net/jsbotanics/latin-name-cinnamomun-camphcra3.png)