Excellent quality for Blackcurrant Extract in Estonia

Excellent quality for Blackcurrant Extract in Estonia Detail:

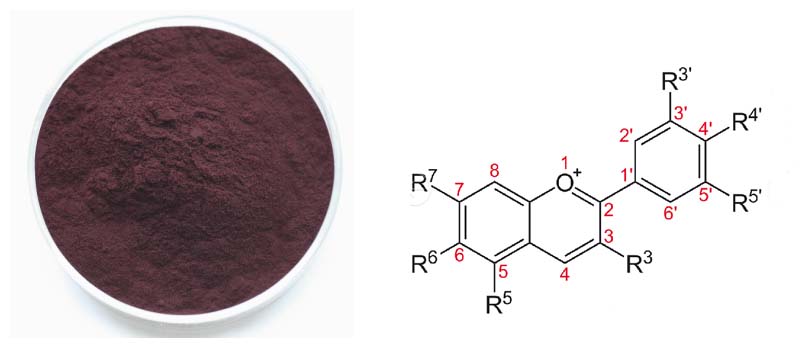

[Latin Name] Ribes nigrum

[Specification] Anthocyanosides≥25.0%

[Appearance] Purple black fine powder

Plant Part Used: Fruit

[Particle size] 80Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Shelf life] 24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[Net weight] 25kgs/drum

[What is Black currant?]

The black currant bush is a 6-foot tall perennial that entered the world somewhere in the regions that include northern Asia and central and northern Europe. Its flowers display five reddish-green to brownish petals. The celebrated black currant fruit is a glossy-skinned berry that carries several seeds laden with marvelous nutritional and curative treasures. An established bush can produce ten pounds of fruit per season

[Benefits]

1. Vision help my eyesight

2. Urinary Tract Health

3. Ageing & Brain Function.

4. Natural Brain Boost

5. Digestion & Fighting Cancer

6. Reducing Erectile Dysfunction

Product detail pictures:

Related Product Guide:

Our primary objective is always to offer our clients a serious and responsible small business relationship, offering personalized attention to all of them for Excellent quality for Blackcurrant Extract in Estonia , The product will supply to all over the world, such as: Slovakia, Albania, Luxembourg, To win customers' confidence, Best Source has set up a strong sales and after-sales team to provide the best product and service. Best Source abides by the idea of "Grow with customer" and philosophy of "Customer-oriented" to achieve cooperation of mutual trust and benefit. Best Source will always stand ready to cooperate with you. Let's grow together!

some tips on how i use rooting hormone to grow plants

-~-~~-~~~-~~-~-

Please watch: “Stop Buying So Much Power! Wrap Your Water Heater.”

-~-~~-~~~-~~-~-

Pumpkin seed !!!!!!.What U know about pumpkin seed ???? .Its not just a seed ….Here are10 health benefits of pumkin seeds….U will be surprised to know the amazing benefits of this small seeds.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!